The Electropolishing Solution for EDM Recast Layer Risks

While the machining method known as Electrical Discharge Machining, or EDM, helps in the development of unique metal parts and parts composed of hard materials, it can leave behind a problematic recast layer composed of re-deposited flecks of metal.

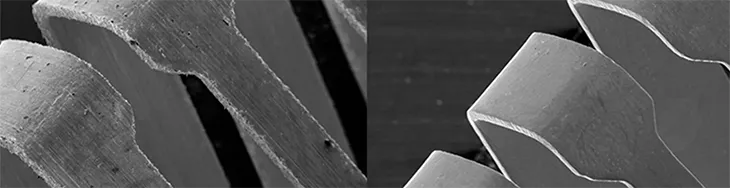

This layer is the result of heat that develops during wire cutting, producing molten material that cools rapidly and hardens on the surface. This false, brittle layer creates a poor surface finish and can leave parts prone to failure. It can introduce variation into the part shape and dimensions, affecting both fit and function. The recast layer can also create a stress point if micro-cracks form, reducing a part’s fatigue life.

In addition, compromised corrosion resistance can occur as the result of the surface contamination and altered surface chemistry that an EDM recast layer can introduce.

The Microscopic Precision of Electropolishing for EDM Recast Removal

For industries like aerospace and medical device manufacturing, such risks are non-starters and an effective solution for removing the recast layer is critical.

While machining methods, including milling and grinding, are sometimes used to remove a recast layer, many parts made from softer alloys or designed with critical geometries are not good candidates for mechanical methods, which can create warping and distortion.

Chemical etching, another potential alternative, can create widely varying stock removal making it a poor choice for parts with critical dimensions.

For all these reasons, many manufacturers of metal parts subjected to EDM turn to electropolishing instead. Electropolishing is precise, consistent and can improve the surface finish of metal parts by up to 50%. Such precision makes electropolishing well-suited for removing surface defects from complex or fragile parts.

How Electropolishing Works to Eliminate EDM Recast Removal

Electropolishing combines an electrolyte solution with an electrical current to strip away a microscopically precise layer of surface material from metal parts. Electropolishing material removal can be controlled to +/- .0002” and removes material from the highest points first to leave a uniformly smooth finish.

Electropolishing can be precisely calibrated to remove only the surface material required to eliminate the recast layer. The thickness of the recast layer can range from .0001” to .001”

Other Advantages of Electropolishing for Critical Metal Parts

In the process of removing the EDM recast layer and other surface defects, electropolishing leaves parts with microfinish improvement of up to 50% with .001” total material removal. This can significantly enhance part durability and fatigue life.

Electropolishing also leaves parts with 30 times more resistance to corrosion than passivation, while also leaving parts in a passivated state.

The electropolishing process is also well-suited for removing burrs, even from fully annealed or hardened parts.

The Advantage of an Experienced Electropolishing Partner

For your metal parts that undergo electrical discharge machining, an experienced electropolishing partner can provide an effective solution for removing the recast layer with precise and consistent results.

Look for an electropolishing specialist experienced in your industry and whose processes include diligent quality control, including careful inspection, testing, analysis and custom racking to ensure high-quality results for fragile or complex parts.